Norrel delivers a complete, fit for purpose waste heat recovery system, the ThermStar System™. ThermStar is engineered for tough industrial and commercial ventilation environments. At the heart of the system is Lepido™, a rugged heat exchanger built specifically to operate in polluted exhaust air, where traditional systems clog or fail.

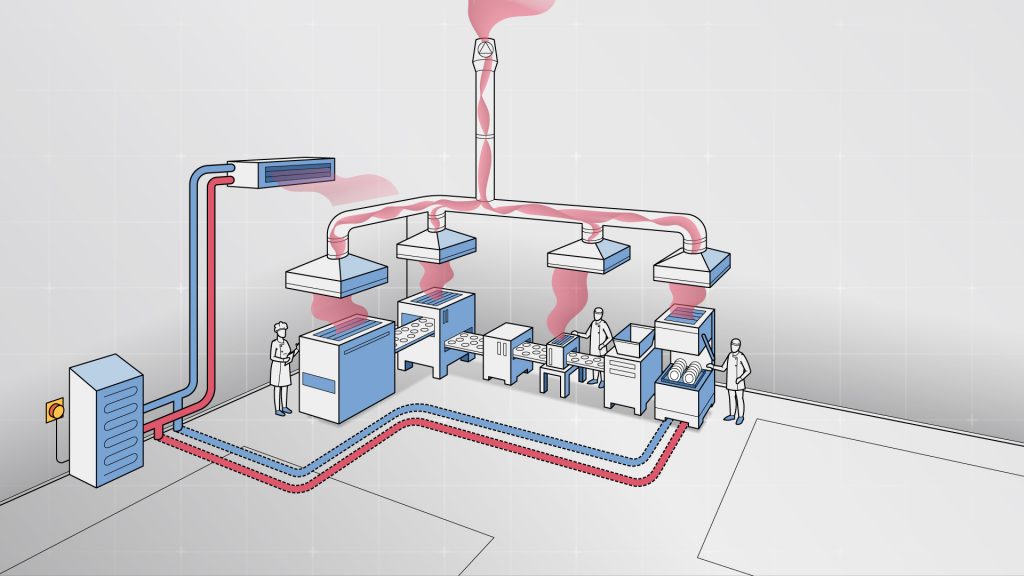

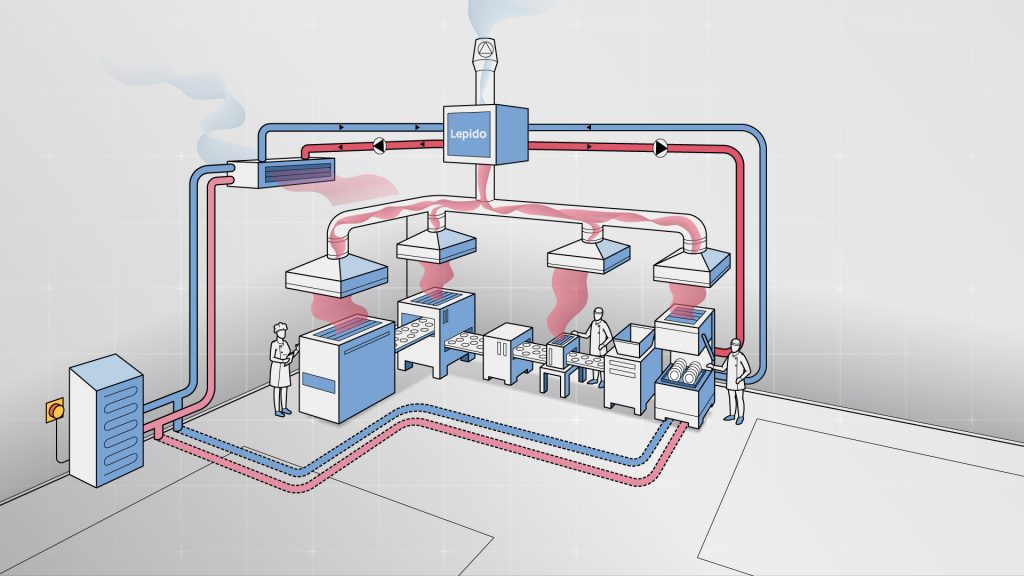

Our system reclaims thermal energy from air streams contaminated with grease, soot, lint, or moisture, and transfers that heat into usable energy, typically to preheat incoming air or water, without disrupting your existing processes.

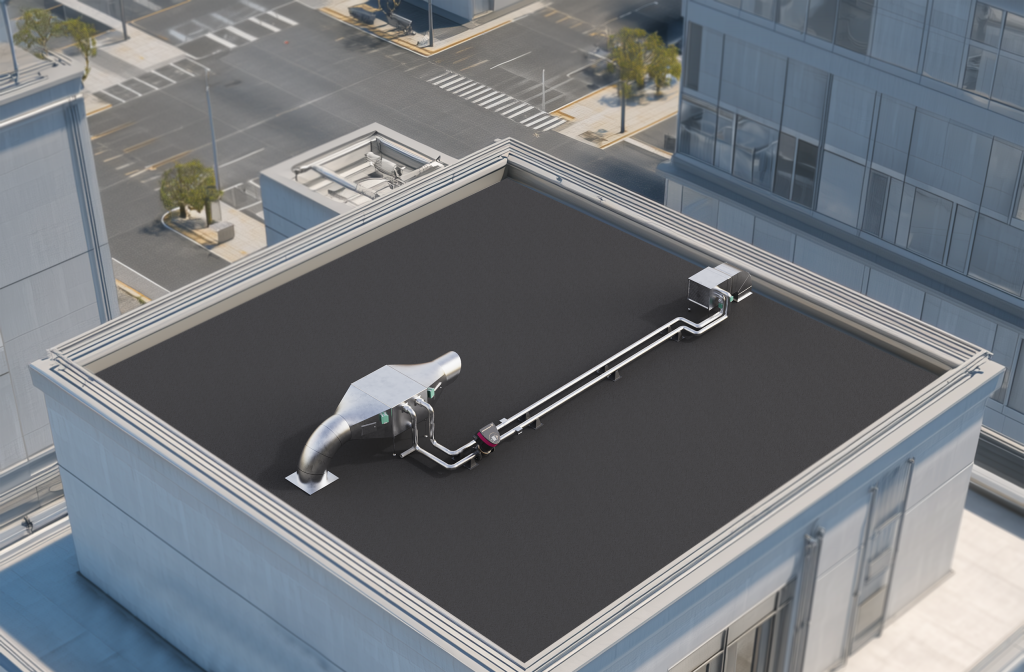

Norrel’s ThermStar System™ combines the power of the Lepido™ unit with a fully integrated solution:

This turnkey solution is designed for fast deployment and long-term reliability by preferred mechanical contractors using our installation guidelines.

Recovers heat from humid, lint and detergent laden exhaust streams in tunnel washers, tumble dryers, and finishing equipment.

See how CWS Workwear uses Lepido to cut energy costs.

Handles grease, steam, and particulates in food production and restaurant exhaust from industrial snack lines to quick-service kitchens.

Case studies: Burger King, Lantmännen Pancake Factory.

Ideal for thermal exhaust in textiles, polymers, foundries, and beyond including challenging contaminants like fibers, resins, and dust.

Explore Sports & Leisure Group and Bruzaholms Foundry.

Reclaim Waste Heat. Energy Savings Delivered

The Swedish innovation Lepido™, the only heat recovery unit engineered specifically to revover energy from particulate laden exhaust air, has earned 41 global patents.

Now available in North America exclusively through Norrel Inc., Lepido forms the heart of our ThermStar System™, turning wasted heat into clean, usable energy for commercial and industrial operations.

In industrial laundries, food processing plants, manufacturing facilities with process heating, and commercial kitchens, exhaust air consistently contains particulates such as grease, lint, soot, and other contaminants. These real-world conditions overwhelm conventional heat exchangers, leading to clogging, fouling, and frequent failure. Lepido™ was engineered specifically to operate reliably in these demanding environments where traditional systems cannot.

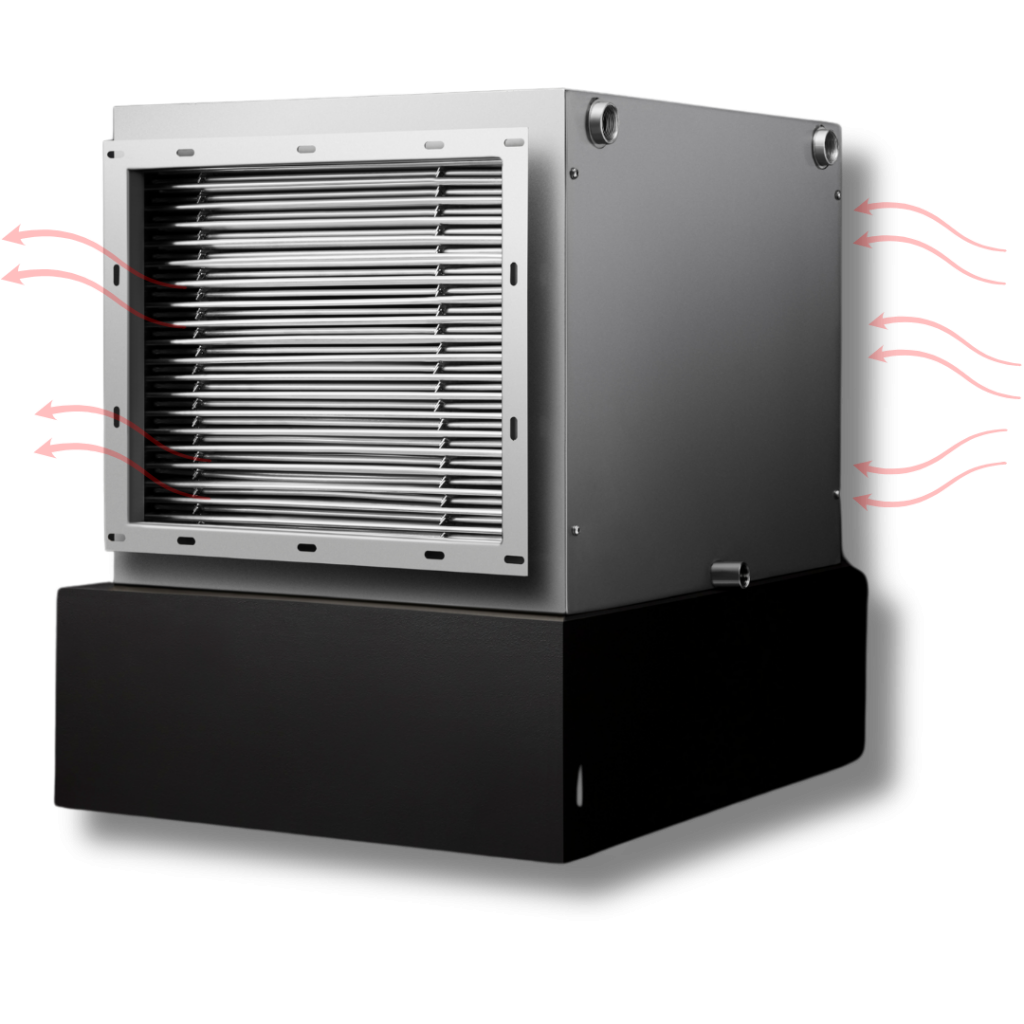

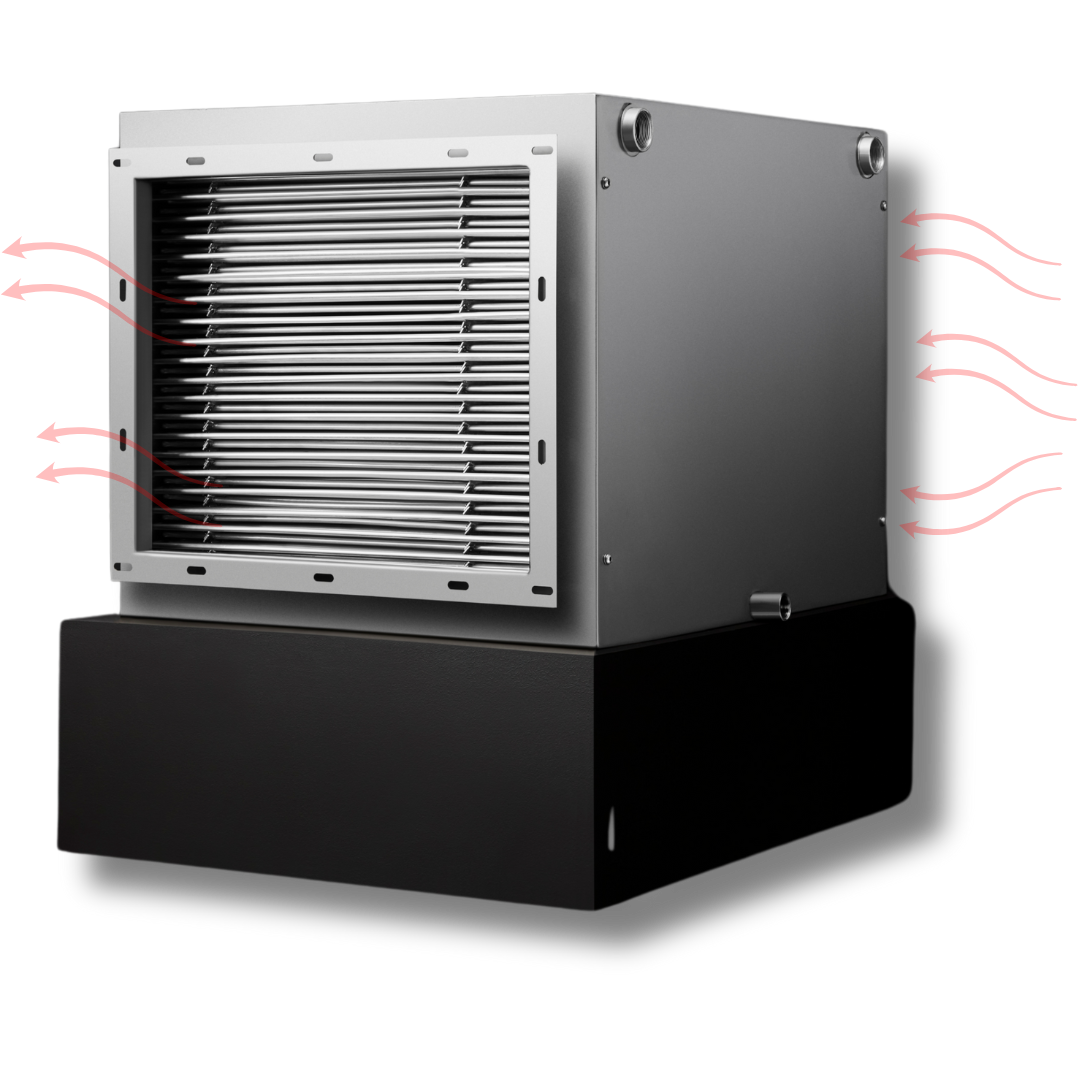

Lepido™ is purpose-engineered for polluted industrial airstreams where uptime and reliability are critical. Its open, finless heat exchanger geometry allows particulates, moisture, and contaminants to pass through rather than accumulate, enabling continuous heat recovery without clogging. Across more than a decade of operation at customer sites, Lepido™ systems have demonstrated 99.9% operational reliability, delivering consistent performance 24/7, year-round in exhaust environments that routinely disable conventional heat recovery technologies.

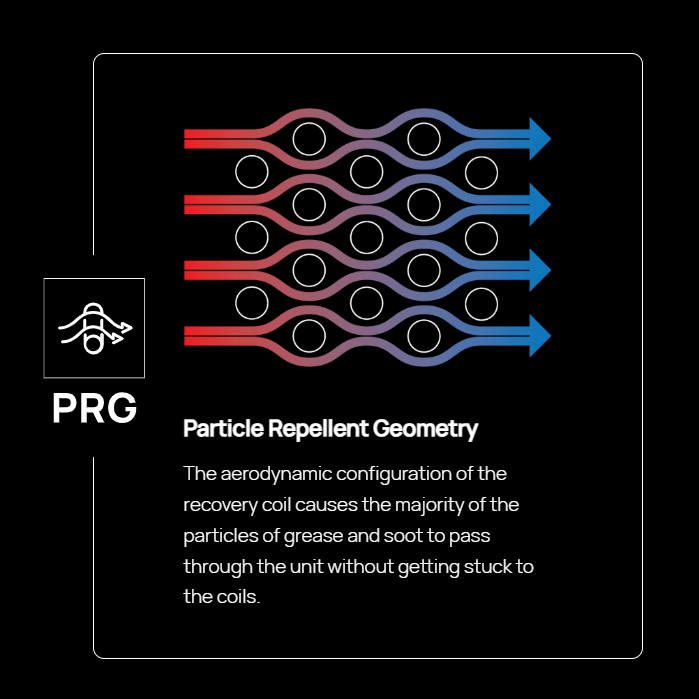

Traditional exchangers clog quickly, but Lepido’s patented Particle Repellent Geometry (PRG®) slows down particulate buildup, preserving high thermal efficiency and reducing maintenance frequency, even in dirty, grease laden exhaust.

Recovers up to 60% of thermal energy, sometimes more, redirecting it to preheat process air, hot water, or HVAC systems. The result: lower energy bills, lower emissions, and faster ROI

Particle Repellent Geometry (PRG), reclaiming waste heat in environments where others can’t.

Unlike traditional heat exchangers that rely on tightly spaced fins, Lepido features a finless, open coil design that works with the natural flow of contaminated air.

Grease, soot, moisture, and other particles pass through the exchanger without clogging or sticking to the surface. This drastically reduces buildup, pressure drop, and the need for frequent maintenance.

Its larger structure allows for ample spacing between coils, creating a unique airflow pattern where particles are repelled rather than trapped. Despite its open design, Lepido maintains the same heat transfer surface area as conventional systems by using 100% counter-current flow and multiple fluid patterns.

Long lasting performance, substantial energy recovery, even in the harshest industrial environments.

Reclaim Waste Heat. Energy Savings Delivered