The ThermStar System™, powered by Lepido™, is built to recover heat from polluted exhaust air where traditional systems fail. Whether installed on rooftops or within technical equipment rooms, our systems integrate into your existing ventilation to capture energy that would otherwise be lost to the atmosphere.

That recovered energy is then reused to preheat Air (for HVAC, dryers, or process equipment) or preheat Water (for boilers, washers, or industrial processes) helping your operation cut energy costs, reduce CO₂ emissions, and accelerate ROI with a dependable, field-proven system.

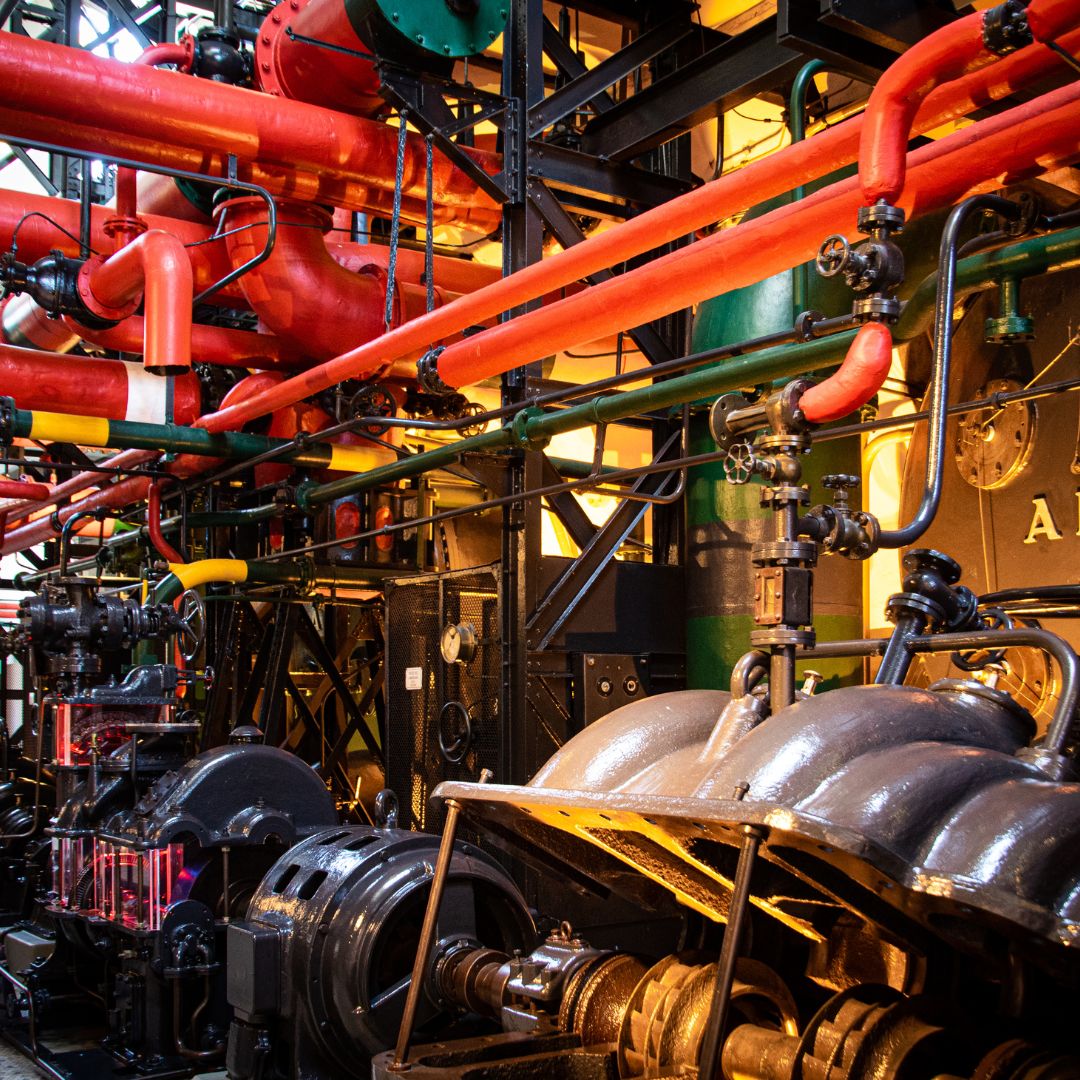

No two industries are alike, however, they all generate waste heat. Lepido™ adapts to the specific challenges of your industry whether that’s grease, soot, lint, moisture, or chemical particulates delivering reliable performance in even the harshest airstreams.

Common Uses:

Ovens, fryers, and steamers emit hot exhaust air filled with grease, vapor, and particulates.

Common Uses:

Kitchen operations generate continuous, contaminated exhaust air containing oils and soot from cooking.

Common Uses:

Drying, curing, and heated process lines release high volumes of thermal exhaust energy containing particulates.

Common Uses:

Casting and machining operations generate extreme temperature exhaust air, often with metal particles, oils, and dust.

Common Uses:

Facilities with pools, spas, or lazy rivers can capture waste heat from pool heaters or kitchens and reuse the heat to warm pool water directly.

Applicable Sites: Hotels, resorts, and aquatic centers

Common Uses:

Recover thermal energy from exhaust air to raise the temperature of boiler makeup water before it enters the system.

Applicable Across: Any location with industrial boilers

Common Uses:

Custom & Engineered Solutions

Every facility is different. If yours is not listed Contact Us. We begin by gathering site-specific data on your exhaust air volume, contaminants, temperature, and intended thermal use.

Our Approach: